NCASS Digital Safety Management System

Save time, reduce hassle and keep your business inspection-ready.

DIY repairs may satisfy a short-term solution but your attempt to repair an appliance may have direct consequences, whereby someone could get hurt or property could be damaged. You could misdiagnose the problem, spend money on the wrong replacement parts and use up your valuable free time trying to painstakingly do something you are not familiar, competent, or qualified to do.

The fact is anyone repairing or servicing a gas appliance who is not appropriately gas safe registered, qualified and competent to do so, is breaking the law!

There is a reason that gas engineers are the only ones legally permitted to work on gas appliances. Familiarity, experience, knowledge, qualification, expertise, and understanding the fundamentals of how appliances work is key to ensuring their safe operation in your working environment.

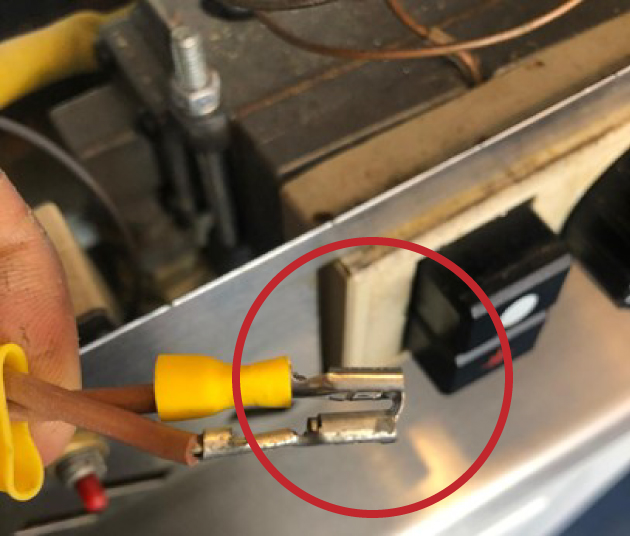

The “DIY-er” could not get their bain-marie to work after connecting it to the gas?!

If you look closely, you will see that they have actually connected the gas hose via the water drain-off valve and not by the gas outlet! Hence why it won’t deliver gas to the appliance! Oops!

With any appliance repair it is essential that the engineer recommissions the appliance to ensure its continued safe use. For example, making sure that the appliance is gas tight, the gas pressure is safe, the flame picture is satisfactory, and checking that gas controls and safety devices work correctly.

It’s really tempting to watch a self-help You Tube video or follow the advice given on social media outlets to diagnose a problem you may have a with a gas appliance and then have a go yourself at a repair.

Our advice – you are not a suitably qualified or competent Gas Safe Registered engineer, so don’t do it! It is not worth the risk. Making a temporary repair may have very real consequences! As the following scenarios indicate.

The following are examples of common DIY Gas Repairs carried out by traders/mobile caterers. We wanted to highlight these to you so you can understand the issues that can arise and why DIY/self-repairs must be avoided.

You have a problem with your appliance. For example, the flame on your bain-marie keeps going out. So, you google the problem and you come across a self-help video on how to change the thermocouple (flame failure device) and assume this must be the answer to your problems. So, you go ahead and implement the video instructions. Initially this does not solve the problem so you change the thermocouple again. This time it works for a couple of days and then fails again. So now you are stuck with the problem and you can’t use your appliance.

The problem could be unrelated to the thermocouple. Instead, it could be related to a faulty MAG valve, or a blocked gas jet creating incorrect pressure (a smaller flame). Or flame lift where the gas and air mix lift the flame out of the thermocouple probe range. Or due to insufficient ventilation making the pilot flame lift off in search of oxygen to burn.

Where DIY repair in this instance has been unsuccessful it is not uncommon to see makeshift brackets, clamps or bent cutlery strapped across gas valves to hold them into an on-position, thus negating the very reason for a flame failure device to be there in the first place.

The gas knobs have been removed on this grill and replaced by bent cutlery positioned over the gas controls enabling them to be continuously in an “on position”.

For details on how flame failure devices/thermocouples work and what they should look like when correctly installed refer to our guide https://www.ncass.org.uk/lpg-safety-in-the-spotlight-suitability-of-appliances-flame-failure-devices/

For example, clamping a broken gas taper knob to a gas valve. On the surface looks like a great repair but in real life this repair has inadvertently allowed the gas tap to activate and allow unburnt gas to fill the oven void. This may be a consequence that you are aware of but without letting everyone else know that the way the appliance now works has changed, can have the potential of a catastrophic incident.

For example, one of our Gas Engineer Partners (GEPs) was recently injured because of such a scenario during a routine gas servicing.

A six-burner range oven had undergone some DIY repairs making the appliance unsafe. A jubilee clip had been used to fasten on a gas taper knob to facilitate the connection, allowing the gas valve to be constantly in the “on” position.

On the surface the appliance looked unchanged. Whilst servicing and going through the initial basic function tests of the hob and then the oven, the GEP who had not been made aware of the DIY repair and the potential for unburnt gas to come into contact with a naked flame source, was suddenly engulfed by a fireball. The GEP suffered second degree burns!

Burn injuries caused by the DIY attempt to repair a gas knob that masked a gas leak.

One of our GEPs recently encountered a trader who had completely disassembled their floor standing fryer in the midst of large public event, in order to clean out the burners. They were attempting to remove the build-up of soot from the burners as the appliance had stopped working.

Aside from breaking the law by attempting work that only qualified gas engineers should undertake, the big risk was with the trader not being able to put the appliance back together again correctly and not carrying out the legally required safety tests (e.g., gas tightness test), to ensure the appliance is safe to use.

The GEP who encountered this trader, got them to immediately stop, and then worked to make sure the appliance was properly serviced, put back together correctly and tested, before it was brought back into use.

What made this incident worse was there was no OPSO regulator fitted to the installation and the brass fitting that formed part of the connection was found to split and was leaking gas. The GEP spotted this and was able to repair it before the gas leakage could become explosive. However, the trader would not have been able to identify this issue.

Cracked brass fitting on the connection to the fryer which was creating a gas leak.

At the same event a different trader was also found to be attempting to assemble their own large gas pipework as well.

This is a good lesson in – “unless you know what you are doing you could be doing more harm than good!”

It is very common for GEPs to identify this scenario – traders who have bypassed the over-heat stats on deep fat fryers!

All fryers must have sufficient temperature control thermostats, designed to detect when the temperature of the oil gets too hot (e.g. exceeds 205oC), and then switches off the fryer. It is a crucial safety feature – preventing the fryer from overheating which could lead to a fire or damage to the appliance.

Sometimes the over-heat stat develops a fault which causes “nuisance tripping” of the fryer (the overheat stat cutting out too early/at low temperatures). This becomes a nuisance to the trader who understandably wants the fryer to work reliably. Some traders have taken to bypassing the heat stat to overcome nuisance tripping and to enable continuous use of their fryers, and in doing so have rendered the appliance unsafe to use. This is instead of arranging the correct repairs to the heat stat so it will work properly and maintain the key safety controls.

Faults on the over-heat stat can arise when the fryer has been positioned on an unlevel surface or if it is bumped, knocked or collided with during transportation – the two probes that make up the over-heat stat can become misaligned. These faults can be easily corrected by a competent gas engineer as opposed to bypassing the device as the example below shows.

Do not attempt this!

The interrupter leads to the overheat stat on a fryer have been deliberately bypassed so the electrical signal remains in a continuous loop – so it does not trip the fryer which remains in continuous use. There is now no safety device to turn off the fryer when the oil over-heats.

If during a routine servicing/inspection a gas engineer identifies that the over-heat stat has been deliberately bypassed and they are not permitted by the owner/responsible person to reinstate the safety controls and make the appliance safe, then they are duty bound to report this to the local authority (H&S enforcing authority). The removal of a key safety control is one of the criteria for reporting under RIDDOR procedures (Reporting of Injuries, Diseases and Dangerous Occurrences Regulations) to the local authority. The breach of gas safety regulations for example failure to maintain key safety devices on appliances could result in enforcement action being taken against the trader.

The temporary DIY repair is unlikely to resolve the problem in the long run and is just delaying the inevitability of appointing a gas engineer to put it right, meanwhile there are often more breakdowns, and the accumulation of problems resulting in bigger repairs and more cost.

Always contact a suitably qualified and competent gas engineer rather than tackling what seems on the surface an easy repair. Without the technical ability to recommission the appliance after the repair, there is no guarantee the appliance will be safe going forward.

Any work to change or repair an appliance must be accompanied by the legally required gas tightness testing etc and recorded on gas safety certification.

Are you looking for a Gas Safe Registered LPG engineer? As well as being Gas Safe Registered, an engineer must be specially qualified to work on LPG installations.

NCASS have a prepared the following free guide which can be downloaded from the Free Resources area of the NCASS Gas Hub website. This can help with checking if an engineer is qualified to work on LPG. It includes a handy guide to commercial catering qualifications and what categories they cover.

How to check a Gas Engineer is qualified to work on LPG installations.pdf

As part of the NCASS commitment to increase standards around LPG usage and safety within the hospitality sector, we have created our Gas Engineer Partnerships (GEPs).

GEPs are qualified and competent Gas Safe Registered LPG engineers that have been carefully selected based on their implementation of the correct mobile LPG standards.

The Gas Engineer Partnerships ensure that our members can access assured and competent gas engineers that meet the standards we have set, so members can rest assured they are acting and operating in compliance.

Find your nearest Gas Engineer Partner (GEP) – tried and trusted engineers competent in LPG. Log into the members only gas engineer page.

For more useful advice and information check out all the previous features “LPG Safety in the Spotlight” on the NCASS Gas Hub.

Check out our free guides on the NCASS Gas Hub Free Resources area. https://www.ncass.org.uk/gas-safety-week-resources/