Digital Food Safety System

Save time, reduce hassle and keep your business inspection-ready.

We previously focused on the safe connection of cylinders with flexible hoses. The safe connection of cylinders also requires the inclusion of an isolation valve, to isolate the gas quickly and safely in the event of an emergency.

This week we will focus on the arrangements required for isolation valves to reliably shut off the flow of LPG for maintenance, repairs, or emergency situations.

Appliance Isolation Valves

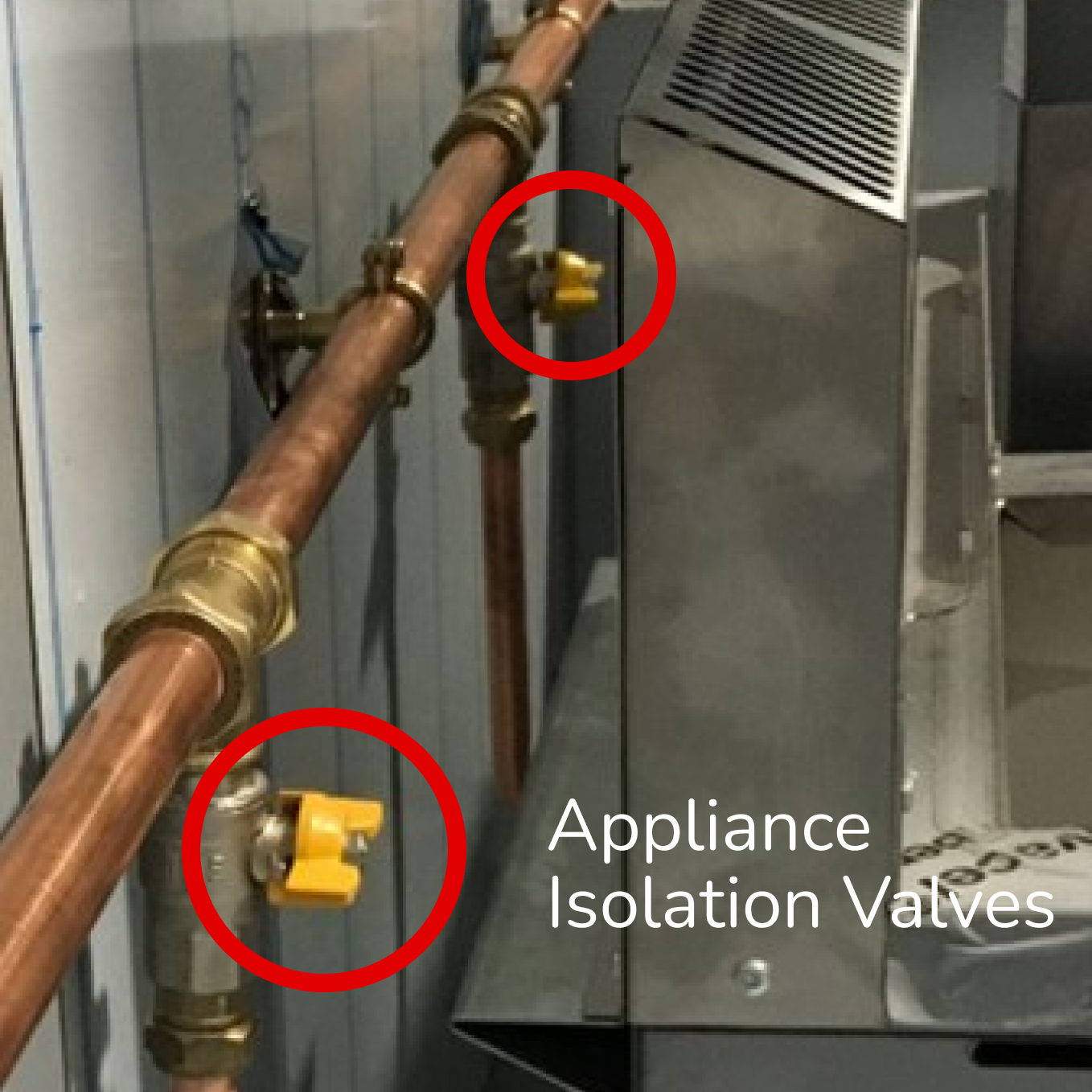

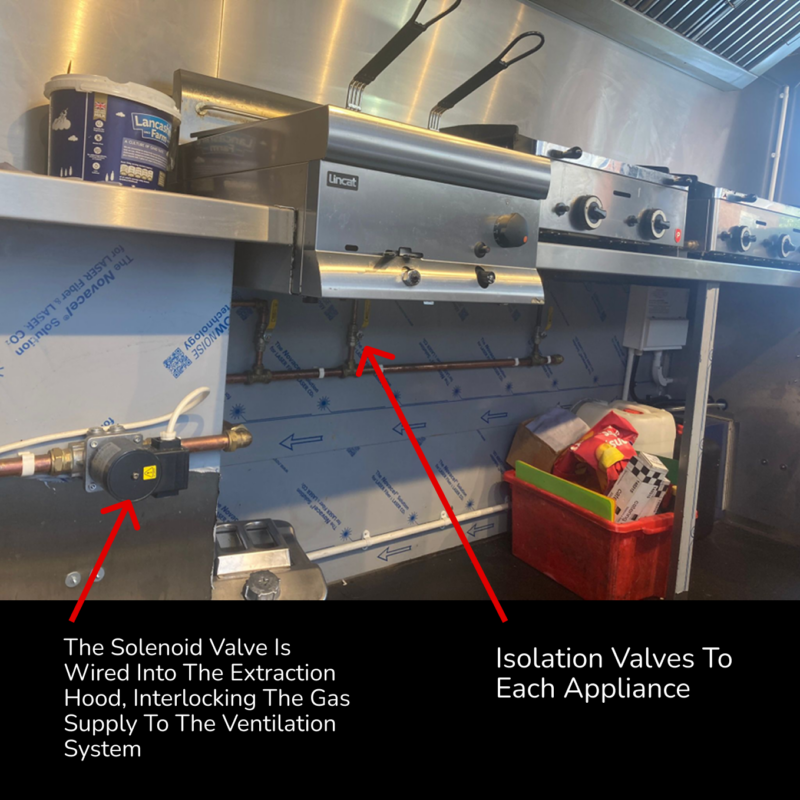

Multiple appliances connected to the same gas line must have individual isolation valves installed in the unlikely event an appliance develops a fault and/or gas leak. This enables the appliance to be isolated without shutting down all the installation.

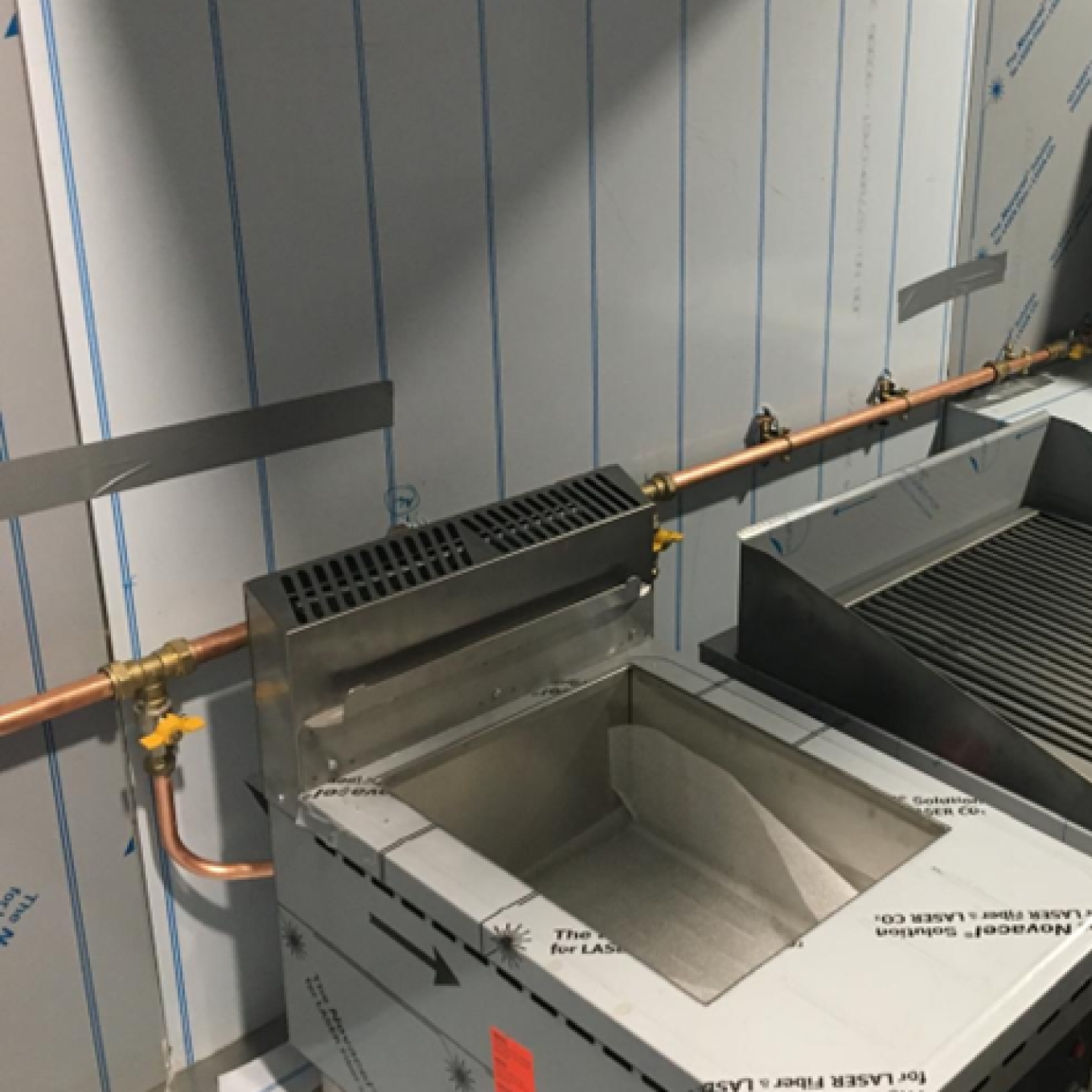

Image – Multiple appliances connected to the same gas line.

Image – Appliance isolation valves fitted for each appliance connected to the same fixed pipe gas line installation.

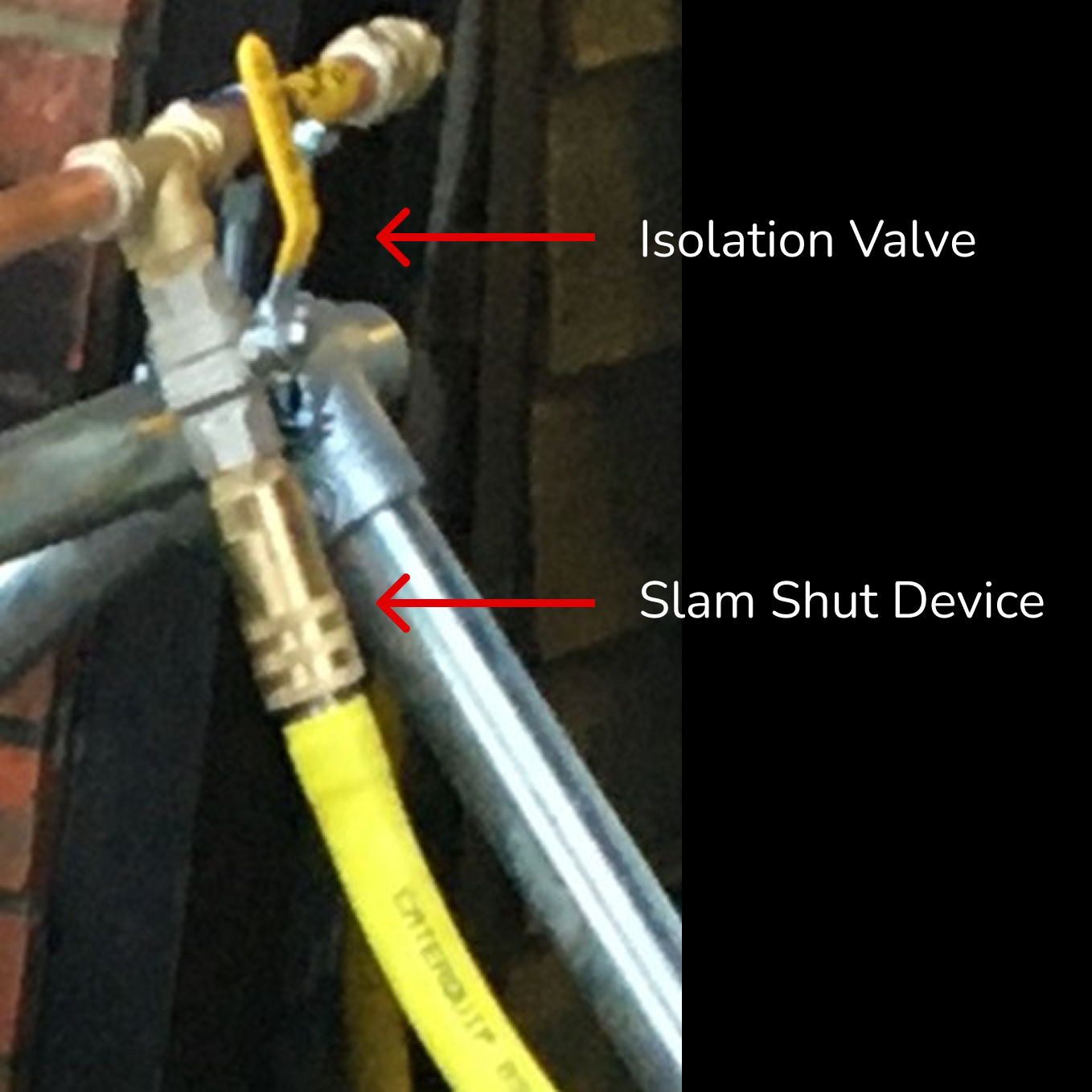

Where appliances are connected to the gas line via a flexible hose (normally to facilitate cleaning) the slam shut connector on the gas line must also incorporate an appliance isolation valve. As it is considered that the slam shut device is an unsuitable method of retaining gas in the pipe by itself (referred to as the “Double-Off”).

Image – A slam shut device fitted with an isolation valve, affixed to a purpose-built rig.

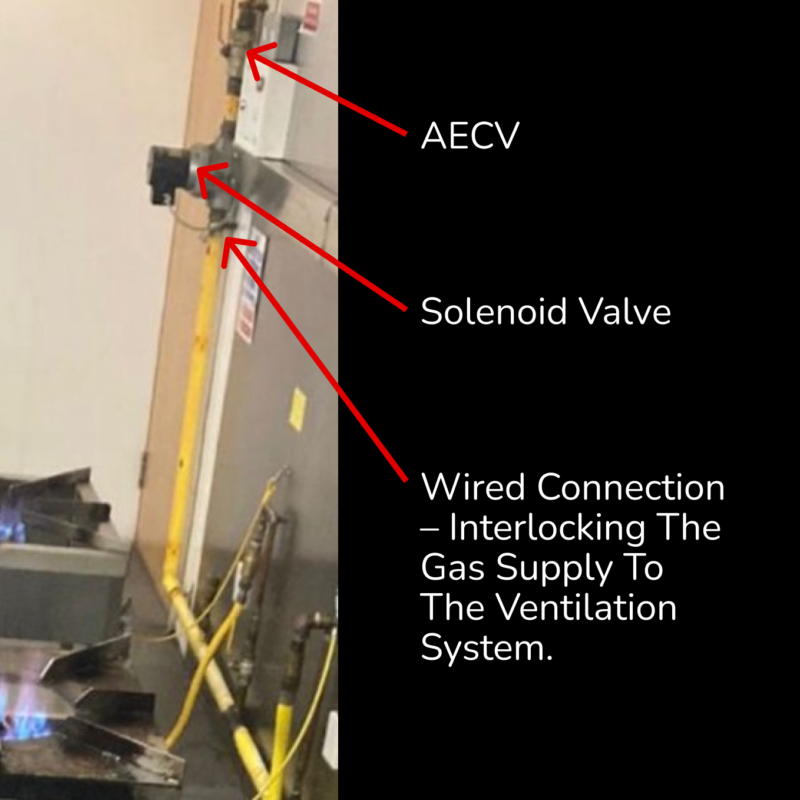

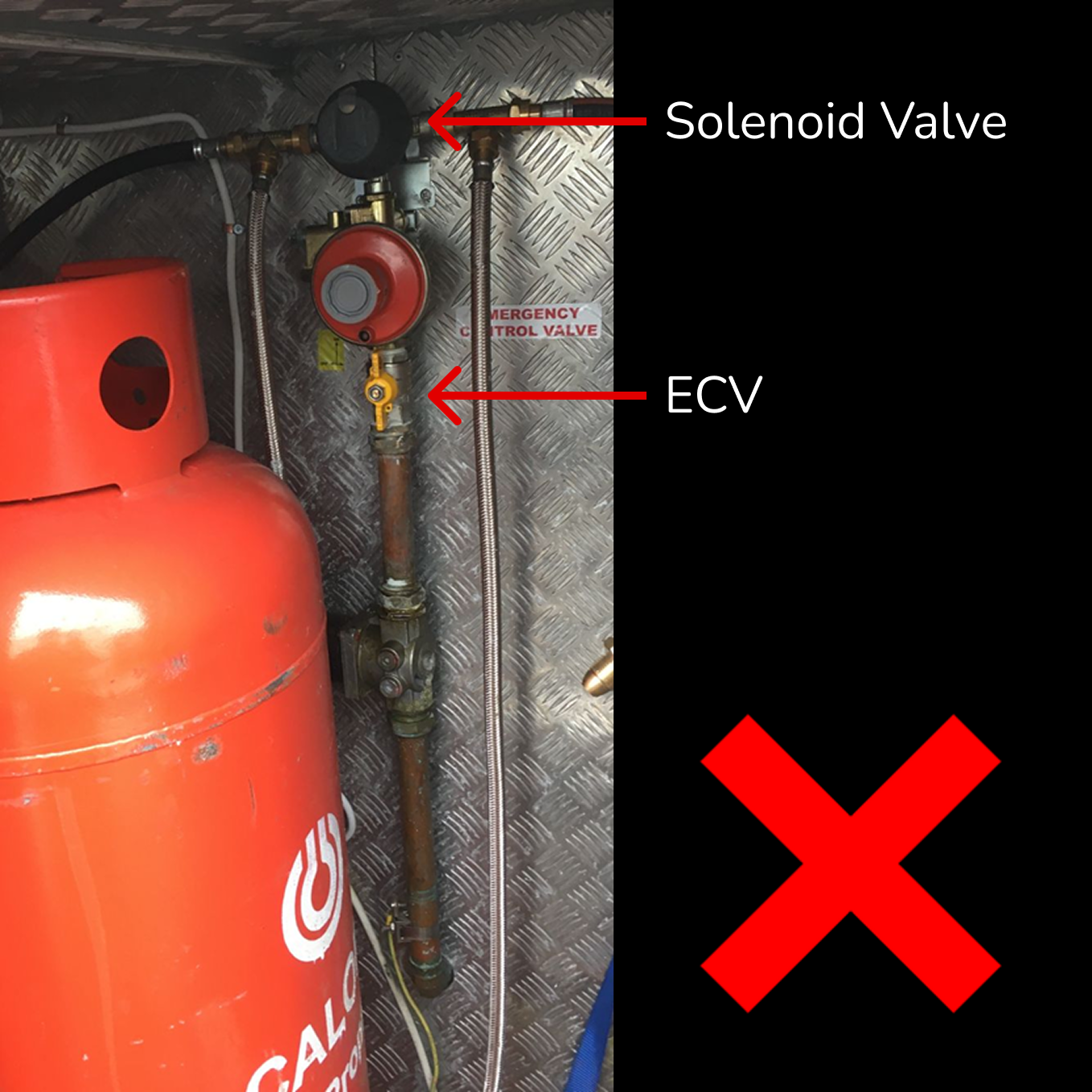

Emergency Control Valves

At the immediate entry of the gas whether it be fixed pipe installation or bulk/multiple cylinders an Emergency Control Valve (ECV) must be present. This is a single acting quarter turn valve to isolate the gas in one movement. In circumstances where this valve is 3m away or more an Additional Emergency Control Valve (AECV) must be installed with suitable labelling being present.

Image – Solenoid Valve and AECV fitted at the entry point of the gas, to isolate the gas supply to the bank of appliances.

Solenoid Valves

Solenoid valves are wired into the extraction system to guarantee quality of air and a safe working environment and to avoid the build-up of dangerous levels of Carbon Dioxide (CO2) which could lead to Carbon Monoxide (CO).

Without the forced extraction and fresh air supply fans switched on, there will be no gas supply to the appliances. The gas supply is therefore interlocked into the ventilation system for safety.

No ventilation/air = no gas.

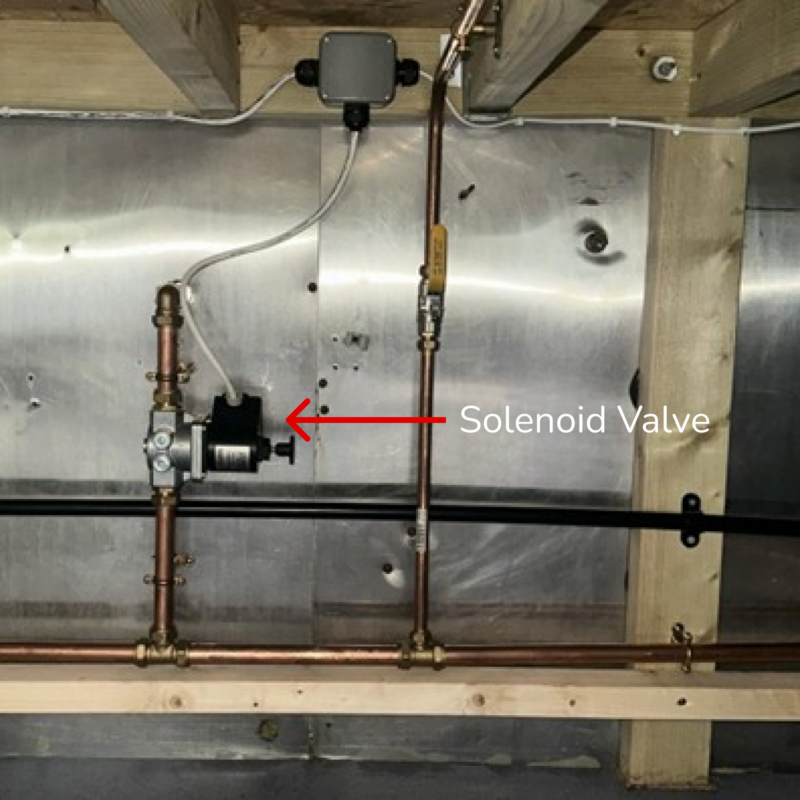

Image – A solenoid valve as part of fixed pipe installation.

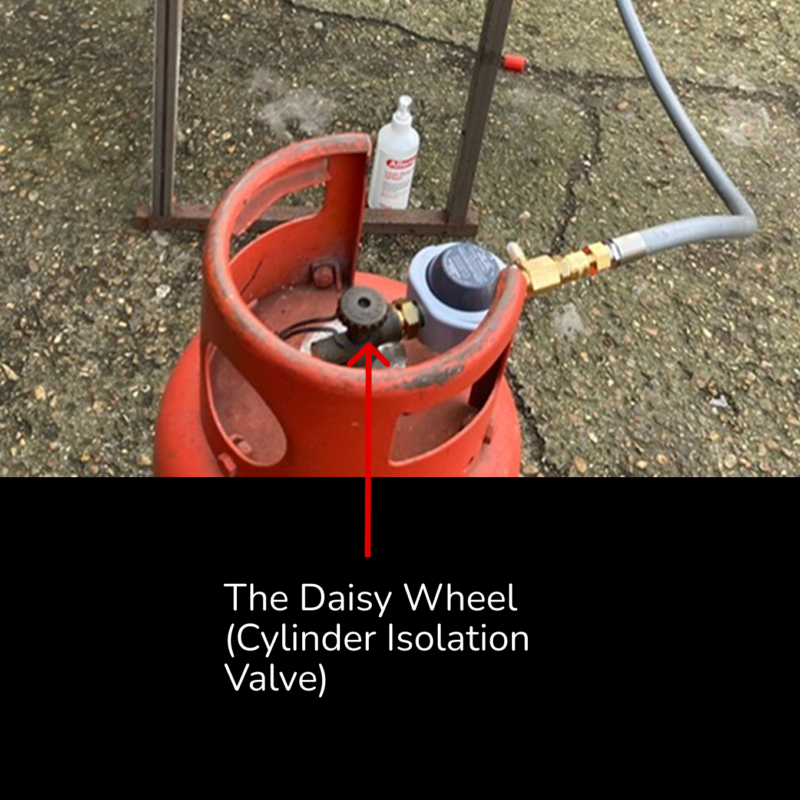

A Single Cylinder Valve

Where a single cylinder is connected to a single appliance, there will be no need for an appliance isolation valve or an ECV. The single cylinder isolation valve in this instance is considered the ECV.

Image – Tightening the Daisy Wheel on the cylinder to the closed position is the EVC

Example of a correct installation

A counter mounted fryer and griddles correctly installed in a mobile catering unit. The fixed appliances are fitted with fixed pipework, and individual isolation valves to isolate the gas to each appliance as necessary. There is an extract canopy fitted because this is a permanent structure and the gas supply is interconnected to the extract ventilation system to ensure there is adequate ventilation (safe air) when the appliances are in use.

Examples of Incorrectly Fitted or Missing Isolation Valves

A solenoid valve installed in an incorrect location. It should not be installed in a cylinder compartment– the solenoid is an ignition source so a minimum distance of 1m is required. It should be fitted outside of the cylinder compartment.

An example of a Slam Shut Valve fitted without an appliance isolation valve.

Before connecting to the flexible hose there must be an isolation valve.

Image – Appliances connected to the same line without isolation valves. Individual appliances should have their own isolation valves.

Note: The incorrect use of orange flexible hosing and jubilee clips.

More information

For more useful advice and information check out all the previous features “LPG Safety in the Spotlight” on the NCASS Gas Hub.

Future “LPG in the Spotlight” features will pressure regulators and the key role they play as part of a correct and safe installation.

Check out our free guides on the NCASS Gas Hub Free Resources area. https://www.ncass.org.uk/gas-safety-week-resources/

Also remember to refer to the NCASS Gas Safety Checklist which is included within the NCASS SMS. The checklist will allow you to comprehensively assess the safety of your LPG set up and details the open and close procedures.

Are you looking for a Gas Safe Registered LPG engineer? Find your nearest Gas Engineer Partner (GEP) – tried and trusted engineers competent in LPG. Log into the members only gas engineer page.