As part of our focus on the safe connection of LPG cylinders, we have previously focussed on suitable flexible hoses and the inclusion of isolation valve(s), to isolate the gas quickly and safely, for maintenance, repairs, or emergency situations.

This week we will focus on the important role of the pressure regulator.

A regulator MUST be fitted onto all LPG installations! It does an important job of reducing the pressure from the cylinder.

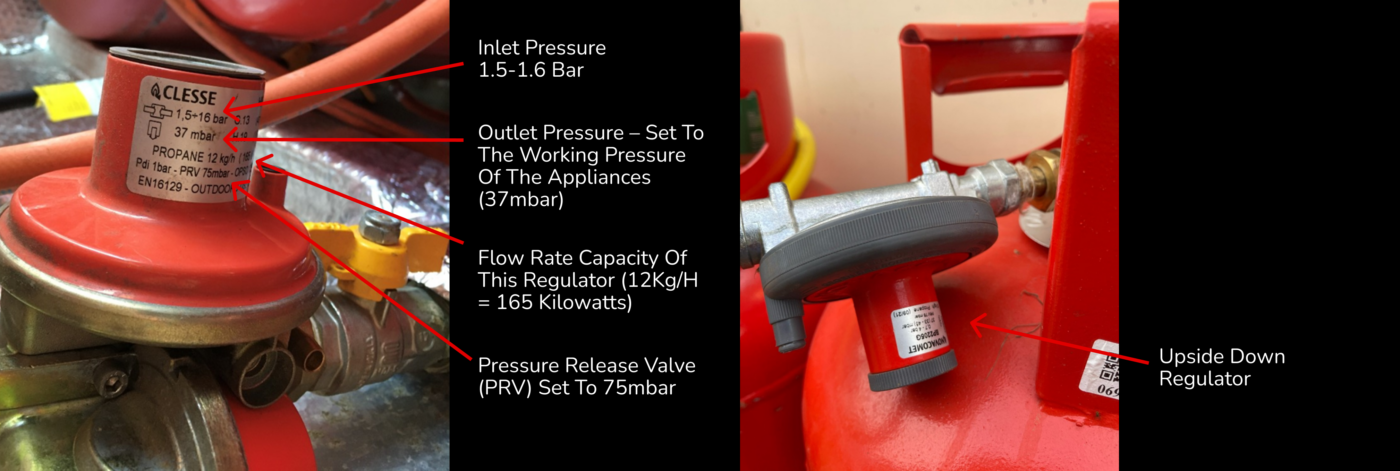

Most appliances approved for use in the UK require a safe supply pressure of around 37mbar. Meanwhile a propane cylinder will supply a much higher pressure of 7-9bar. (Note: 1 bar = 1000mbar).

Why the need for a regulator?

The regulator when connected to the installation will ensure that the right amount of gas is released at the correct pressure. It uses a valve system to control the flow of gas, releasing small amounts of gas into the surrounding area, to prevent the build up of pressure. This controlled release of gas is why it is so important that propane cylinders are sited outdoors in well-ventilated spaces and are never stored or used indoors. Otherwise, the release of gas by the regulator could accumulate indoors and become ignitable.

Without the regulator the pressure within the appliance or its connection could become excessive leading to a catastrophic explosion! Therefore, the importance of the regulator cannot be ignored.

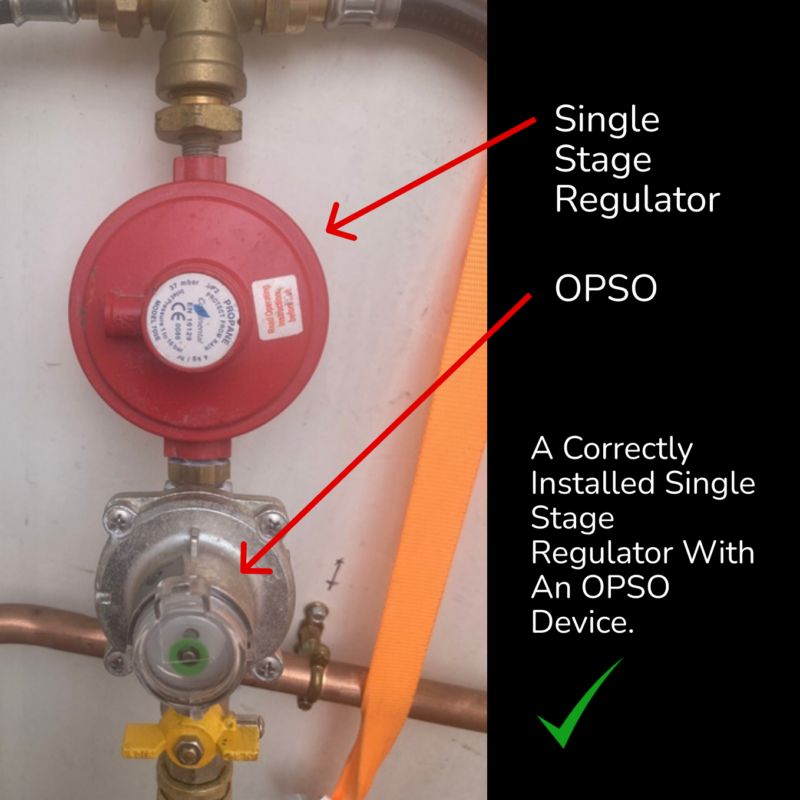

Single Stage Regulator

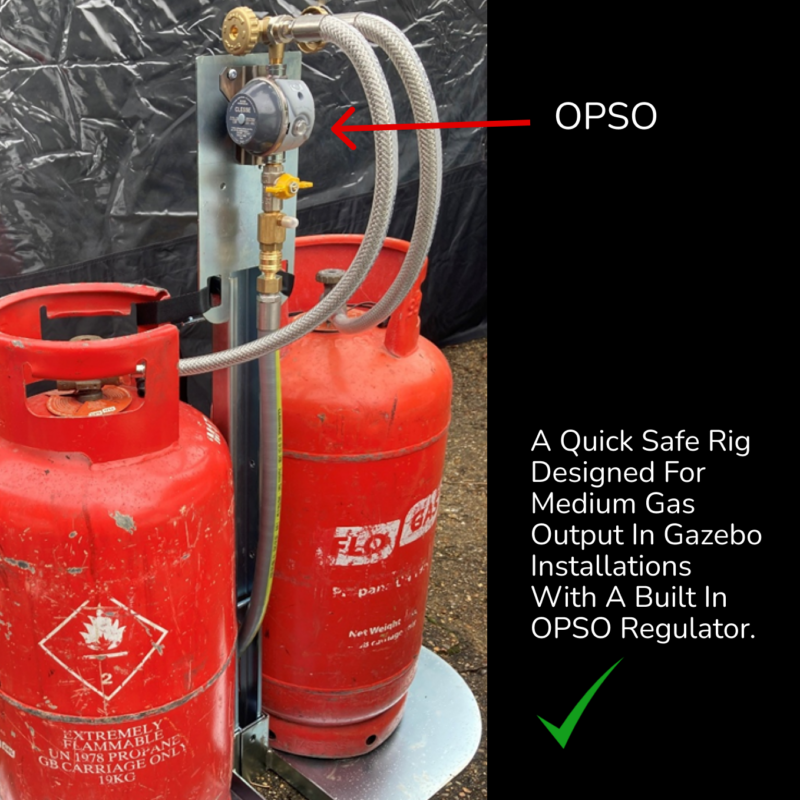

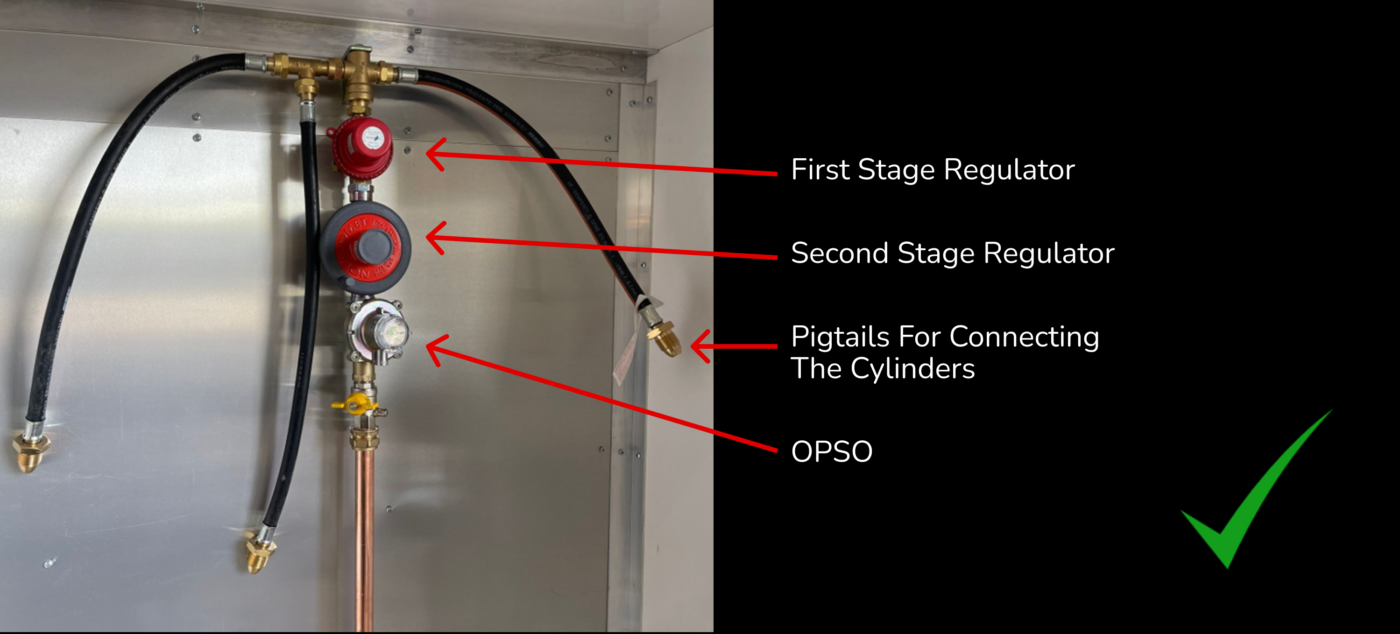

There are various types of regulators (first stage, second stage and final stage) which will allow different flow rates and are set to different pressures. Most commonly a single stage regulator will be used however, regardless of which one is used, they must conform to EN 16129

This type of regulator alone is acceptable when a single appliance is connected to a single cylinder. On its own it is not suitable when there are multiple cylinders in use.

Example of a single stage regulator:

It is important for the regulator to be attached the right way around – face up. This one is incorrect. We need the regulator to be sited above the offtake valve of the cylinder to avoid possible liquid ingress.

Featured Training

Featured Training